Our News

Printing And Labeling Techniques For Cylindrical Packages

Printing And Labeling Techniques For Cylindrical Packages

Summary

Printing and labeling techniques for cylindrical packages encompass a variety of methods and technologies employed to enhance the functionality and visual appeal of packaging used across numerous industries. These techniques are crucial in the production of cylindrical containers, which include a wide range of products such as food, beverages, personal care items, and pharmaceuticals. The importance of effective printing and labeling lies not only in product branding and consumer recognition but also in regulatory compliance and sustainability considerations, making this topic highly relevant in today's market.

The process of printing on cylindrical packages involves several methods, including flexography, screen printing, and digital printing, each with its own set of advantages and challenges. Flexography is favored for high-volume applications due to its efficiency and capability to produce vibrant graphics. In contrast, screen printing is often employed for smaller runs and intricate designs, while digital printing is becoming increasingly popular for its quick turnaround times and cost-effectiveness in low-volume orders. These diverse techniques must be tailored to the specific substrates used, such as paper, plastic, or metal films, to achieve optimal results.

Labeling techniques, such as sleeve labeling and pressure-sensitive labeling, play a vital role in product presentation and compliance with labeling regulations. Sleeve labeling allows for comprehensive branding opportunities on the entire surface of a container, while pressure-sensitive labels provide ease of application and versatility across different materials. Innovations in these methods, including sustainable materials and automation, reflect the industry's response to growing consumer demand for eco-friendly packaging solutions and efficient production processes.

The industry faces significant challenges, including navigating stringent regulations, addressing sustainability concerns, and adapting to rapid technological advancements. As manufacturers strive for efficiency and compliance, they must balance quality control with the need for speed and cost-effectiveness in their operations. The ongoing evolution of printing and labeling technologies is essential for meeting these challenges and ensuring that cylindrical packages continue to meet the needs of consumers and brands alike.

Types of Cylindrical Packages

Cylindrical packaging is widely utilized in various industries for both functional and aesthetic purposes. Commonly found in the form of custom packaging tubes, product displays, and promotional items, these packages can be made from different substrates depending on the desired application and characteristics of the product being packaged.

Substrates Used in Cylindrical Packaging

Paper and Cardboard

Paper and cardboard are frequently employed materials in the production of cylindrical packages. They are often used for items such as packaging tubes and product displays, offering a lightweight and customizable option for brands. However, these materials exhibit certain challenges, particularly moisture sensitivity, which can lead to absorption and potential degradation of printed graphics.

Plastic Materials

Modern cylindrical packaging increasingly incorporates plastic substrates such as rigid vinyl PVC, polypropylene, and polyester (PET). These materials provide several advantages over paper, including enhanced durability and moisture resistance. Plastic substrates are particularly valuable for flexible packaging, accommodating various printing techniques while ensuring the integrity of the contents inside.

Metal Films

In addition to paper and plastics, cylindrical packages can also be made from metallic films. These films are advantageous for their barrier properties, protecting contents from light, moisture, and air, which is essential for preserving product quality.

Advantages and Disadvantages of Cylindrical Packaging

Cylindrical packaging offers several benefits, including ease of handling, efficient space utilization during storage and transport, and the ability to print graphics that wrap around the package seamlessly. However, there are disadvantages to consider. For instance, cylindrical packages may only be suitable for flat materials, and they can be subject to wear and tear, which could affect the appearance and functionality of the package.

Printing Techniques

Printing techniques have evolved significantly over the years, adapting to various market needs and technological advancements. This section explores some of the key printing methods utilized in the production of cylindrical packages, highlighting their unique characteristics and applications.

Flexography

Flexography, or flexo printing, is the predominant choice for high-volume packaging applications, especially on corrugated substrates. It utilizes an inked image carrier to transfer graphics onto various materials efficiently. This method excels in producing vibrant graphics while maintaining gentle handling of substrates. Flexo printing also integrates multiple processes into a single pass, allowing for greater efficiency compared to traditional offset printing, which typically requires additional finishing processes.

Advantages of Flexography

Flexography is highly versatile, capable of printing on an extensive range of substrates, including porous and absorbent materials. Its ability to produce high-quality prints at rapid speeds makes it particularly advantageous for manufacturers looking to optimize production efficiency and reduce costs in large-scale operations.

Screen Printing

Screen printing has undergone substantial transformation since its inception, particularly since the 1960s when two-color machine presses were commonly used. Modern screen printing employs screens made of various mesh sizes covered with chemical emulsions, which are essential for creating prints with rich colors. The process involves placing a film containing a positive image on the screen, exposing it to light, and subsequently washing the screen to remove unexposed emulsion, thereby allowing ink to flow through in the desired areas. This technique is especially effective for small-volume prints, as it produces vibrant, durable images suitable for diverse materials, including textiles and packaging.

Flat Screen Printing

In flat screen printing, the exposed screen is positioned directly over the substrate. Ink is placed in front of a squeegee, which then moves across the screen, forcing the ink through the mesh and creating the print. This method is particularly suitable for straightforward designs and applications.

Rotary Screen Printing

Rotary screen printing offers a variation where the squeegee is fixed within the screen. As the mounted cylinder rotates, it pushes ink through the mesh, allowing for continuous printing on substrates that move beneath the screen. This method is advantageous for longer runs and provides consistent quality.

Digital Printing

Digital printing represents a significant leap forward in printing technology, as it allows for direct printing from digital files without the need for plates. This method employs high-resolution inkjet or laser printers, making it an ideal choice for small-volume orders and samples. Digital printing offers cost-effectiveness and speed, catering to modern demands for quick turnaround times. However, it tends to be more expensive per print compared to other methods, particularly for larger volumes.

Labeling Techniques

Labeling techniques for cylindrical packages have evolved to meet the demands of modern packaging, focusing on efficiency, sustainability, and visual appeal. Various methods are employed to ensure accurate label application and enhanced product presentation.

Sleeve Labeling

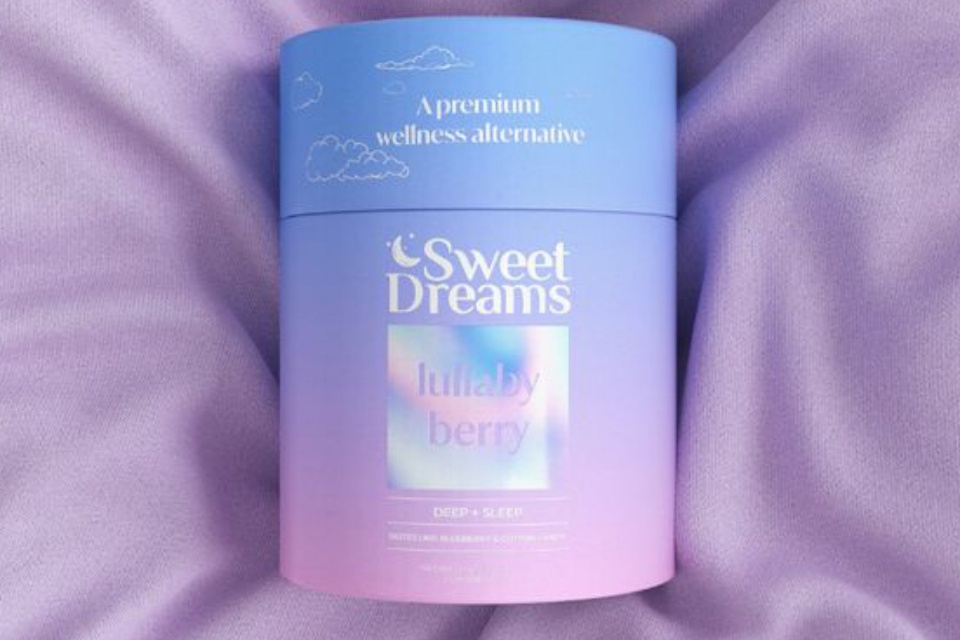

Sleeve labeling involves the use of full-body labels made from heat-shrinkable film, which is placed around the container and then shrunk using heat or steam, resulting in a tight, tamper-evident seal. This method provides a 360-degree canvas for branding and graphics, enabling eye-catching designs that enhance shelf appeal. Sleeve labelers are commonly utilized for premium beverage bottles, food containers, personal care products, and pharmaceutical packaging.

Modern Enhancements

Recent advancements in sleeve labeling technology include integration with printing systems for high-quality graphics, as well as the use of sustainable materials such as bio-based plastics and post-consumer recycled content. Automation has also become a hallmark of modern sleeve labeling processes, allowing for high-speed, precise application while minimizing human error.

Hot Melt Glue Labeling

Hot melt glue labeling employs heated adhesive to apply labels to various packaging materials like cardboard, plastic, and metal. This technique is known for its strong adhesion, making it suitable for challenging environments, including those with moisture or cold temperatures. Hot melt glue labelers are prevalent in the beverage and food industries, as well as in pharmaceutical and cosmetics packaging.

Applications and Enhancements

This labeling method integrates well with vision systems to ensure precise label placement, contributing to a clean and professional appearance. Hot melt glue labelers also support pressure-sensitive labels, which are essential in high-volume production lines due to their high-speed operation and versatility.

Pressure-Sensitive Labeling

Pressure-sensitive labeling utilizes adhesive backing on self-adhesive labels, which are activated by applying pressure to the packaging surface. This method is advantageous for its high-speed operation and adaptability to various label materials and shapes. The application process is clean and efficient, making it a popular choice across multiple industries.

Advanced Features

Modern pressure-sensitive labelers can be integrated with barcode printing and scanning systems, enhancing traceability and allowing for real-time product monitoring throughout the supply chain. These labelers also support smart labels, enabling interactive consumer experiences through QR codes or NFC tags that provide additional product information.

Wrap-Around Labeling

Wrap-around labeling is a technique where labels encircle the entire cylindrical container, providing a continuous, seamless application that enhances the product's aesthetic appeal. This method is particularly effective for complying with stringent labeling regulations, as it allows ample space for important information such as dosage instructions and ingredient lists.

Advantages

The advantages of wrap-around labeling include efficient space utilization, reduced complexity in inventory management (as it often requires only one label), and the ability to visually differentiate product ranges through diverse designs and colors. This method is ideal for cylindrical products like bottles and jars, improving both consumer recognition and shopping experience.

Substrate Compatibility

In the realm of printing and labeling techniques for cylindrical packages, substrate compatibility is paramount to achieving high-quality results. Various substrates, such as self-adhesive labels, flexible packaging, and folding cartons, each exhibit unique behaviors during the printing process, necessitating careful consideration by operators.

Importance of Substrate Selection

Selecting the appropriate substrate is crucial for the overall quality and efficiency of the printed product. In flexo printing, for instance, film substrates are particularly favored due to their versatility, durability, and ability to support high-speed printing while maintaining exceptional print quality. However, these materials can pose challenges; for instance, issues like mottling—characterized by uneven ink lay-down—are common when using certain substrates.

Key Considerations

When working with a diverse array of substrates, three key considerations must be addressed:

Temperature

Temperature plays a critical role in the printing process, influencing how inks interact with substrates. Proper temperature management can reduce distortion and strain on the substrate, allowing for precise movement and positioning during printing.

Web Tension

Maintaining appropriate web tension is essential for ensuring consistent ink application across various substrates. Improper web tension can lead to issues such as smudging or uneven printing, which are detrimental to the quality of the final product.

Material Characteristics

Understanding the material characteristics of substrates is vital for selecting compatible inks and printing techniques. For example, the choice of ink must align with the substrate to avoid issues during the printing process, particularly when dealing with flexible packaging materials.

Regulatory Considerations

The printing and labeling industry for cylindrical packages faces a complex regulatory landscape that can significantly influence operational practices and market dynamics. A primary concern is the stringent regulations governing the labeling of hazardous materials. Compliance with these regulations often necessitates substantial investments in research and development, creating barriers particularly for smaller companies that may lack the financial resources to meet these requirements.

In regions such as Hong Kong, recent amendments to waste management policies have emphasized increased recycling rates and a reduction in single-use plastics. This shift aligns with broader environmental commitments and necessitates that cylindrical can producers invest in eco-friendly materials, including biodegradable coatings and lightweight alloys, to comply with these regulations and avoid penalties. The drive towards a circular economy is prompting innovation in can design, aiming to facilitate easier recycling and remanufacturing processes, which could reshape supply chain dynamics and product differentiation strategies.

Globally, regulatory bodies, including the Environmental Protection Agency (EPA) in the United States, are intensifying environmental standards that compel manufacturers to adopt sustainable packaging practices. Companies that proactively align with these evolving regulations by investing in sustainable innovations and transparent reporting are likely to secure competitive advantages and foster consumer trust. Conversely, failure to adapt could lead to operational restrictions and reputational risks, undermining market share in an increasingly eco-conscious environment.

Furthermore, the rise of direct-to-container digital printing technology presents new regulatory considerations, as it reduces the need for label substrates and could potentially decrease costs, thus challenging traditional labeling practices. As regulatory frameworks continue to evolve, companies in the cylindrical packaging industry must remain vigilant and adaptive to ensure compliance and capitalize on emerging opportunities in sustainability and efficiency.

Challenges in Printing and Labeling

Printing and labeling cylindrical packages present a unique set of challenges that manufacturers must navigate to ensure quality and efficiency. These challenges stem from the complex nature of the substrates used, the need for high-quality finishes, and the operational requirements of different printing techniques.

Substrate Variability

One of the primary challenges in printing on cylindrical packages is the variety of substrates that can be used. Each material—ranging from plastic to glass and metal—has distinct characteristics that affect the printing process. Printers must carefully consider the compatibility of inks and printing techniques with each substrate, as improper combinations can lead to issues such as poor adhesion, fading, or flaking over time. Additionally, factors like temperature and web tension must be meticulously controlled to accommodate the unique behavior of each material during the printing process.

Quality Control

Ensuring consistent quality throughout the production run is another significant challenge. With the increasing automation in digital printing, manufacturers benefit from real-time monitoring and adjustments to improve quality and reduce waste. However, achieving the desired visual appeal and durability of labels still requires rigorous quality control measures. This involves continuous checks for color accuracy, print alignment, and the integrity of finishes, especially when special effects such as embossing or foil stamping are applied.

Production Speed and Efficiency

While modern printing technologies allow for high-speed production, the setup time can be a bottleneck, particularly for complex print runs involving multiple colors or intricate designs. This is especially true for flexographic printing, which, despite its advantages for large-scale production, may not be as efficient for shorter runs due to longer setup times. Balancing the need for speed with the quality requirements of premium packaging poses a challenge for manufacturers aiming to meet tight deadlines without compromising on the end product's aesthetics and functionality.

Sustainability Considerations

In the current market, sustainability has emerged as a critical concern. The choice of materials and inks can significantly impact the environmental footprint of printing operations. Manufacturers face the challenge of sourcing eco-friendly materials while maintaining production efficiency and product quality. The trend toward using biodegradable and recyclable options necessitates an ongoing commitment to research and development to create effective and sustainable solutions that align with consumer preferences.

Technological Adaptation

Finally, keeping pace with rapid technological advancements can be challenging for manufacturers. The integration of artificial intelligence (AI) and robotics into printing processes enhances production rates and consistency, but it also requires continuous adaptation to new technologies and workflows. Companies must invest in training and equipment upgrades to fully leverage these advancements, which can be a barrier for smaller businesses seeking to remain competitive in a fast-evolving market.

Future Trends

Sustainability and Eco-friendly Practices

The printing and labeling industry is increasingly focusing on sustainability as a primary concern. With the rise in environmental awareness, practices such as the use of recycled paper and eco-friendly inks have gained traction. These inks, derived from natural and renewable resources like vegetable oils and soy, significantly reduce the ecological footprint compared to traditional petroleum-based inks. Additionally, energy-efficient printing presses are becoming standard, which consume less energy while maintaining high-quality output.

Technological Advancements

Technological innovation remains a key driver in the evolution of printing techniques. Digital printing, in particular, is revolutionizing the industry by enabling direct transfers from digital files to substrates without the need for printing plates. This not only reduces setup times but also makes short-run and on-demand printing more economically viable. Moreover, advancements such as high-speed inkjet and electrostatic ink-jet printing are expanding applications in industrial and packaging sectors, offering high levels of customization and efficiency.

Emerging Label Formats

In-mold labeling is emerging as a significant trend within the labeling market. Although it currently holds a small share of the global market at just 2%, its potential for manufacturing economies and efficiencies makes it appealing to brand owners, especially in the consumer food and drink sectors. This labeling format is gaining traction in Europe, with growth observed across the Americas, signaling a shift in consumer and manufacturer preferences.

Shift Towards Direct-to-Container Printing

Another promising area is the direct-to-container digital print technology, which eliminates the need for a label substrate. This not only reduces costs but also offers a competitive edge against traditional labeling methods. As brand owners become more interested in this technology, it could reshape the dynamics of the labeling industry, pushing it toward greater efficiency and sustainability.

Regional Market Growth

The future market opportunities are notably shifting towards Africa and the Middle East, which experienced a growth rate of 3.3% last year. In contrast, mature markets like North America and Europe saw modest growth rates of 2.1% and 1.9%, respectively. This indicates a potential for expansion and investment in regions that are currently developing, highlighting a strategic pivot for businesses seeking growth in the coming years.

Challenges Ahead

Despite these promising trends, the industry faces challenges, including rising costs for transportation and energy, exacerbated by the disruptions caused by the COVID-19 pandemic. These factors may impact the availability of supplies across the value chain, necessitating adaptability and strategic planning by industry players to navigate the evolving landscape.

Categories

Latest News

Contact Us

Contact: Aaron Lee

Phone: +8613570866244

Tel: +8675529490260

Add: Li Songlang 2nd Industrial Zone,No.18,FengTang Rd,Guangming New District