Our News

Using Collapsible Boxes For Seasonal Or Bulk Orders

Using Collapsible Boxes For Seasonal Or Bulk Orders

Summary

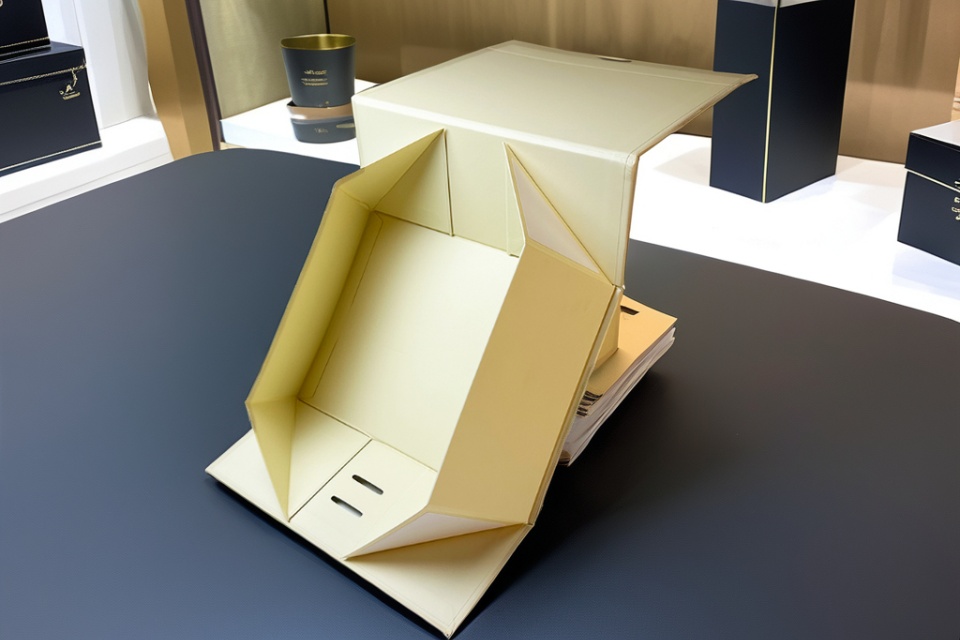

Using Collapsible Boxes for Seasonal or Bulk Orders refers to the practice of utilizing flexible packaging solutions that can be folded flat when not in use, significantly enhancing storage and transportation efficiency. As industries strive to optimize logistics and reduce waste, collapsible boxes have gained prominence in sectors such as e-commerce, retail, and manufacturing. Their design allows for space-saving storage, lower transportation costs, and a smaller environmental footprint, making them a noteworthy component of modern supply chain strategies. This method reflects a growing commitment to sustainability as businesses adapt to consumer demands for eco-friendly practices and materials.

Collapsible boxes come in various materials, including plastic, metal, and paperboard, each offering distinct advantages tailored to specific applications. Plastic options, such as those made from high-density polyethylene (HDPE), are favored for their durability and hygiene, particularly in food and pharmaceutical industries. Metal boxes, constructed from steel or aluminum, are utilized in industrial contexts for their heavy-duty strength, while paperboard alternatives are often chosen for their versatility and customization potential, appealing to environmentally conscious consumers.

The advantages of using collapsible boxes extend beyond cost efficiency and sustainability; they also enhance operational flexibility and improve customer experiences. By facilitating effective return policies and streamlining logistics, these packaging solutions help businesses navigate fluctuations in demand, particularly during peak seasons or for bulk orders. However, challenges remain, including ensuring structural integrity, managing production scalability, and balancing cost management with environmental considerations.

The growing adoption of collapsible boxes signals a transformative shift in packaging practices, driven by advancements in materials science and consumer awareness. As companies continue to innovate, the focus on sustainability and functionality is expected to reshape the future landscape of packaging solutions, reflecting the dual goals of operational efficiency and environmental responsibility.

History

The concept of collapsible packaging can be traced back to the need for more efficient storage and transportation solutions in various industries. Early iterations of collapsible boxes emerged as manufacturers sought to reduce waste and improve logistics, particularly in the post-World War II era when resource conservation became a priority. The design and structural engineering of these packaging solutions were foundational to their success, focusing on maximizing durability while minimizing material use.

As industries evolved, so too did the materials and technologies used in collapsible packaging. By the late 20th century, advancements in materials science led to the introduction of high-density polyethylene (HDPE) and polypropylene (PP), which provided not only flexibility and durability but also the potential for a more sustainable packaging approach. This transition was spurred by growing environmental concerns, prompting businesses to adopt packaging solutions that minimized their carbon footprint.

In the 21st century, the rise of e-commerce and consumer demand for sustainable practices significantly accelerated the adoption of collapsible boxes. Companies recognized the benefits of these innovative designs, including their ability to fold flat for space-saving storage, which ultimately led to reduced shipping costs. The integration of advanced digital printing technologies allowed for greater customization of collapsible packaging, meeting the unique needs of businesses and consumers alike.

Today, collapsible boxes are used across various industries, including retail, food and beverage, and pharmaceuticals. They not only provide practical benefits but also support environmental sustainability by reducing waste and promoting a circular economy. As the market continues to innovate, collapsible packaging remains an essential component of modern supply chain strategies, reflecting an ongoing commitment to efficiency and environmental stewardship.

Types of Collapsible Boxes

Collapsible boxes come in various types, each designed to meet specific needs in packaging, storage, and transportation. These boxes can be constructed from different materials, including plastic, metal, and paperboard, and offer a range of features to enhance usability and brand presentation.

Plastic Collapsible Boxes

Plastic collapsible boxes dominate the market due to their lightweight nature, durability, and resistance to corrosion. They are commonly made from high-density polyethylene (HDPE) or polypropylene (PP), which provides a high strength-to-weight ratio and excellent resistance to chemicals and moisture, making them suitable for both indoor and outdoor applications. These boxes are ideal for industries such as food, pharmaceuticals, and logistics, where durability and hygiene are paramount. The ability to easily fold these boxes when not in use allows for efficient storage and transportation, making them a popular choice in supply chain operations.

Metal Collapsible Boxes

Metal collapsible boxes, typically constructed from steel or aluminum, are known for their heavy-duty strength and load-bearing capacity. These boxes are frequently used in industrial settings for transporting heavy machinery parts, bulk materials, and automotive components. Their robust design allows them to withstand extreme temperatures and harsh environmental conditions, which is essential for sectors such as automotive, aerospace, and defense. The longevity and structural integrity of metal containers make them a reliable choice for demanding applications.

Paperboard Collapsible Boxes

Paperboard collapsible boxes are valued for their versatility and eco-friendliness. Made from materials like kraft paperboard, these boxes are easily customizable, allowing brands to create unique packaging solutions that reflect their identity. They are suitable for various applications, including retail and e-commerce, and offer an economical option for transporting products. Additionally, advancements in printing and structural design have led to more innovative uses of paperboard, such as incorporating reinforced elements for enhanced protection. With options for sustainable materials like grass boxboard, these collapsible boxes are increasingly favored by environmentally conscious businesses.

Composite and Specialty Boxes

Innovative composite materials are also being utilized in the production of collapsible boxes. These hybrid solutions combine different substrates to leverage the best properties of each material, enhancing strength and reducing weight while improving sustainability. Specialty collapsible boxes may feature advanced functionalities, such as temperature-sensitive indicators or printed electronics for brand engagement, catering to specific market needs and consumer preferences.

Each type of collapsible box offers distinct advantages, making them suitable for a wide range of applications in seasonal and bulk order contexts. The selection of the appropriate box type depends on factors such as product nature, environmental conditions, and branding requirements.

Advantages

Using collapsible boxes for seasonal or bulk orders presents several significant advantages that enhance operational efficiency and promote sustainability.

Cost Efficiency and Reduced Freight Costs

One of the primary benefits of collapsible boxes is their ability to minimize transportation and storage costs. Their design allows for flat packing when not in use, which can save up to 60% of storage space in industrial settings. This space-saving capability not only optimizes warehouse utilization but also reduces the overall costs associated with storage and transportation. The reduced volume during shipping leads to lower freight costs, which is especially advantageous for businesses managing high-volume shipments.

Environmental Impact

Collapsible boxes contribute positively to environmental sustainability. By choosing reusable containers over single-use packaging materials, companies can significantly decrease their reliance on plastic bags and other disposable items. Many collapsible options are manufactured from recyclable materials and are designed to have a minimal environmental footprint throughout their lifecycle. The production of these sustainable packaging solutions typically consumes less water and energy compared to conventional materials, further aligning with contemporary brand values focused on eco-friendliness. This shift not only reduces waste but also enhances brand perception among environmentally conscious consumers.

Versatility and Customization

Collapsible boxes are versatile and can be customized to meet specific logistics and storage requirements, making them suitable for a variety of industries. Their design allows for easy portability and convenient storage, adapting to the dynamic needs of businesses that manage seasonal or bulk orders. This flexibility extends to their use in diverse applications, from warehouse relocation to general shipping needs, ensuring businesses can maintain operational efficiency regardless of fluctuations in demand.

Extended Product Lifecycle

The reusability of collapsible boxes leads to an extended product lifecycle, allowing them to be utilized for hundreds of cycles without compromising their integrity. This durability ensures that companies can rely on their packaging solutions for extended periods, ultimately resulting in long-term cost savings and reduced environmental impact due to less frequent replacement.

Improved Customer Experience

Finally, effective management of return policies, including procedures for returns and exchanges, is enhanced through the use of collapsible boxes. These boxes are designed to facilitate efficient return shipments, further optimizing logistics and improving the overall customer experience. By investing in such sustainable and practical solutions, businesses can foster customer loyalty and build a positive brand image in an increasingly eco-conscious market.

Applications

E-commerce

As e-commerce continues to expand, the demand for innovative packaging solutions has risen significantly. Collapsible boxes are particularly well-suited for online retail and direct-to-consumer shipping, as they can be designed to withstand the rigors of transit while also enhancing the unboxing experience for consumers. Their space-saving design allows for efficient storage and transportation, which is essential for businesses managing a large volume of shipments.

Retail Environments

Collapsible boxes have emerged as a versatile solution in retail settings, particularly for boutiques and specialty stores that handle fragile or high-value items. These boxes provide a secure and cushioned environment, minimizing the risk of damage during transportation. Furthermore, customization options for these collapsible shopping boxes can enhance a brand's image through high-quality screen printing of intricate designs or logos, transforming them into stylish accessories that encourage repeat use by customers. This approach not only adds value for consumers but also reinforces the retailer's commitment to sustainability and quality.

Industrial Use

In industrial contexts, collapsible boxes are invaluable for organizations that require efficient inventory management. These boxes help keep raw materials and finished products organized and accessible, which is critical in fast-paced manufacturing environments. Additionally, the ability to fold these boxes when not in use leads to significant space and cost savings, making them an attractive option for businesses looking to optimize their storage solutions.

Cost Efficiency

Collapsible boxes also offer notable cost savings, particularly for bulk orders. They facilitate lower per-unit prices and ensure a consistent supply of packaging materials, which simplifies procurement and inventory management for retailers. The manufacturing efficiencies associated with these boxes can lead to approximately 20-30% cost savings compared to traditional rigid boxes, especially in applications such as magnetic gift boxes designed for specific product dimensions.

Sustainability

Sustainability is a growing concern across industries, and collapsible boxes provide an eco-friendly alternative to traditional packaging methods. By using reusable materials and reducing waste, these boxes help companies meet their sustainability goals while also appealing to environmentally conscious consumers. Their adaptability for various applications—from grocery stores to high-end boutiques-underscores their role as a key component in modern, sustainable retail strategies.

Best Practices

Employee Training and Awareness

Comprehensive training and raising awareness among employees about sustainable packaging practices are crucial for effective use of collapsible boxes in seasonal or bulk orders. This ensures that all staff members understand the importance of material conservation and the benefits of using collapsible solutions.

Quality and Safety Standards

Establishing clear quality and safety standards is fundamental for managing collapsible containers. These guidelines should be documented and accessible to all employees involved in handling the containers. Implementing these standards promotes accountability and facilitates proper training, which is essential for maintaining the integrity of the packaging system.

Maintenance and Condition of Containers

To optimize the functionality of collapsible boxes, it is important to ensure that they are free of debris or product before collapsing. This practice not only prolongs the lifespan of the containers but also guarantees that they remain in peak condition for future use. Additionally, regular inspection and maintenance should be performed to identify and address any wear or damage to the containers promptly.

Customization and Functionality

Collapsible boxes can be customized to meet specific needs, including the integration of smart technologies such as RFID tags for inventory tracking. This capability enhances operational efficiency by allowing businesses to monitor their packaging and streamline logistics processes effectively. Customization options, such as drainage holes and ergonomic handles, can further improve the usability of the boxes in various workflows.

Innovative Material Selection

Utilizing advanced materials in the production of collapsible boxes can significantly enhance their durability and functionality. By carefully selecting materials that can withstand various environmental conditions, companies can ensure that their packaging solutions remain robust and reliable over time. The combination of strong materials with innovative manufacturing techniques guarantees that collapsible boxes not only meet but exceed performance expectations in the logistics sector.

Space Optimization and Inventory Management

The collapsible design of these boxes allows for optimized storage and transportation, reducing their volume by up to 80% when not in use. This feature leads to lower shipping costs and improved space utilization in storage facilities, which is especially beneficial during peak seasons or when managing bulk orders. By standardizing box sizes and shapes, companies can streamline inventory management and reduce the risk of stockouts or overstocking.

Ongoing Research and Development

Continued investment in research and development is essential for improving collapsible packaging solutions. By staying informed about the latest innovations and best practices in packaging technology, businesses can adapt their strategies to meet emerging challenges effectively. This proactive approach not only enhances durability but also aligns with sustainability goals and consumer expectations.

Challenges

The use of collapsible boxes for seasonal or bulk orders presents several challenges that need to be addressed to ensure their effectiveness and efficiency in storage and transportation.

Structural Integrity

One of the primary concerns is maintaining structural integrity during use. Although collapsible boxes are designed for reusability, they must withstand the rigors of transportation and handling without compromising their shape or load-bearing capacity. Advanced engineering approaches, such as the incorporation of reinforced structural elements and effective folding mechanisms, are essential to ensure these boxes retain their strength throughout their lifecycle. However, there is a risk that inadequate design or material selection may lead to failures, especially under varying load conditions or when subjected to pressure and crush tests.

Material Quality and Sustainability

Selecting the right materials is critical, as the durability of packaging is influenced by the type of materials used. Balancing eco-friendliness with strength is increasingly necessary due to consumer demand for sustainable solutions. However, the challenge lies in sourcing materials that are both sustainable and capable of providing the required structural integrity without incurring additional costs or sacrificing performance.

Quality Control and Production Scalability

Quality assurance is another challenge when scaling production. As production volumes increase, ensuring consistent quality across batches becomes vital. Implementing automated inspection systems and training quality control teams on best practices are necessary steps, yet they require significant investment and continuous improvement efforts to adapt to the latest industry standards and innovations. Furthermore, managing customization options while maintaining production efficiency poses a logistical challenge that can affect overall operational effectiveness.

Environmental Considerations

Collapsible boxes must also address environmental considerations throughout their lifecycle. This includes ensuring that the design minimizes waste during production and that the boxes can be easily recycled or repurposed at the end of their use. Companies face the challenge of implementing eco-friendly practices while still managing costs and operational efficiency, which can often lead to trade-offs that may not align with sustainability goals.

Cost Management

Finally, managing the costs associated with collapsible boxes is a significant challenge. While these boxes can reduce storage space and transportation costs due to their ability to collapse, the initial investment in high-quality materials and robust design can be substantial. Businesses must weigh the benefits of reduced transportation and warehousing costs against the expenses incurred in manufacturing and maintaining collapsible boxes. Balancing these factors is crucial for maximizing the economic advantages of using collapsible packaging solutions.

Future Trends

Growth in Alternative Materials

As environmental concerns rise, manufacturers are increasingly investing in innovative materials for collapsible boxes that reduce reliance on traditional plastic. The move towards sustainable packaging solutions is expected to reshape the market, driven by stricter regulations and consumer demand for eco-friendly products. This trend is not only confined to reducing plastic usage but also includes the exploration of hybrid materials that enhance durability and sustainability, such as recycled fibers and natural reinforcements.

Geographic and Industry Expansion

There is significant potential for collapsible box packaging to penetrate new markets and industries, particularly in emerging economies where consumer lifestyles are evolving. Industries such as gourmet foods, craft products, and even industrial chemicals represent untapped opportunities for growth. This expansion will likely be facilitated by the increasing disposable income of consumers, which tends to influence purchasing decisions and drive demand for collapsible packaging options.

Technological Advancements

Advancements in automation and loT technologies are set to revolutionize the production of collapsible boxes. These technologies enable better synchronization of production lines, real-time diagnostics, and improved throughput visibility, which can lead to increased efficiency and reduced costs. As manufacturers adopt smart manufacturing techniques, the overall quality and consistency of collapsible boxes are expected to improve significantly.

Customization and Modularity

The demand for customizable and modular packaging solutions is rising, particularly for tools and other products that require specific storage configurations. Companies are responding to this trend by innovating designs that cater to diverse consumer needs, thereby creating more organized and efficient storage systems. This adaptability in packaging design is anticipated to be a key factor driving the market forward in the coming years.

Focus on Durability and Functionality

As brands prioritize damage-free delivery, there is a growing emphasis on the design and structural engineering of collapsible boxes. Companies are increasingly employing advanced materials and innovative design techniques to enhance the protective capabilities of their packaging. This focus not only improves the safety of goods during transit but also enhances the overall user experience, ensuring that packaging meets both functional and aesthetic demands.

Continuous Improvement in Sustainability Practices

Moving forward, companies will need to engage in regular audits and updates of their environmental policies to align with global sustainability standards. This commitment to continuous improvement in sustainable practices will not only enhance the durability of packaging products but will also contribute positively to environmental conservation efforts. By adopting greener practices, the collapsible box market is expected to witness substantial growth and innovation, paving the way for a more sustainable future in packaging.

Case Studies

Overview of Collapsible Boxes in Various Industries

Collapsible boxes have demonstrated their effectiveness across multiple sectors, particularly in subscription box services, the food and beverage industry, and the automotive sector. The adaptability and space-saving qualities of these boxes have enabled businesses to optimize their operations while enhancing customer satisfaction.

Subscription Box Industry Transformation

The subscription box industry has experienced significant growth, necessitating innovative packaging solutions to meet unique challenges. Traditional rigid gift boxes often resulted in excessive storage costs and shipping inefficiencies. In contrast, collapsible gift boxes have transformed this landscape by offering a flexible design that accommodates various product heights and maintains structural integrity, allowing subscription services to adapt to fluctuating product assortments seamlessly.

By adopting collapsible gift boxes, companies have reported a reduction of over 60% in logistics and storage costs compared to traditional packaging. This economic advantage is further bolstered by the streamlined production process, which utilizes advanced visual positioning technology for efficient manufacturing, thereby minimizing waste and ensuring consistent quality across thousands of units.

Food and Beverage Sector Adaptation

In the food and beverage industry, collapsible containers have become essential as the demand for sustainable packaging grows. These containers not only facilitate space-saving storage but also cater to the increasing need for reusable and environmentally friendly packaging solutions. The sector is predicted to witness rapid growth in the usage of collapsible food containers as consumers and businesses prioritize sustainability in their operations.

For example, several companies have implemented collapsible water containers, recognizing their utility in outdoor activities such as hiking and camping, thus expanding their market reach while promoting environmentally responsible practices.

Automotive Industry Efficiency

The automotive sector stands out as a leading user of collapsible and foldable containers, holding a market share of over 31% in 2024. These containers are instrumental in the transportation of heavy-duty components and machinery parts, providing stackability and reusability that significantly enhance logistical efficiency. Companies in the automotive value chain, including OEMs and Tier 1 suppliers, have increasingly adopted collapsible solutions for line-side inventory handling and warehousing, thus optimizing their operations for just-in-time manufacturing.

The emphasis on cost-effective storage and transportation in the automotive sector has driven demand for collapsible containers, leading to a market that emphasizes space-saving solutions while maintaining high standards of operational efficiency.

Categories

Latest News

Contact Us

Contact: Aaron Lee

Phone: +8613570866244

Tel: +8675529490260

Add: Li Songlang 2nd Industrial Zone,No.18,FengTang Rd,Guangming New District